5 Frequent Alternator failure causes

The alternator is a component that plays an important role in producing electricity in the car. The alternator has a function to charge the battery until used for other electrical systems when the engine is running (such as lights, radio, ac, etc.).

If the alternator is damaged, all the electric power used in the car will only come from the car battery. When the electricity supplied from the battery runs out, the car will break down.Read: #5 Signs of car alternator problems

This article will share information on car problems about 5 Frequent Alternator failure causes. What are they? Check out the 5 Frequent Alternator failure causes below.

1. The Integrated Circuit (IC) Regulator is damage

The alternator problem that occurs most often first is a faulty IC regulator. IC regulator regulates the voltage generated by the stator coil so that the voltage that comes out can always be stable on the preferred voltage. So, the alternator can use to charge the car battery.

A stable voltage can prevent the other electrical components in cars from burning, damage, or breakdown.

We can indicate a bad IC regulator on the alternator from the battery warning indicator light that turns on. Or in certain cases, a damaged IC regulator can also make the car battery boil due to overcharge.

2. Carbon brush is worn out

The next alternator failure that often occurs is worn-out carbon brushes. The carbon brush is a component that can conduct electric current to rotating rotor components. Yes, the electric current from the car battery can continue to flow to this rotor component because of the carbon brush component.

Because this carbon brush works by rubbing against the slip ring on the rotor, the carbon brush can run out, causing the electric current from the battery to be cut off.

The disconnection of the electric current going to the rotor will result in the electrical energy produced (read: how the alternator works). The electric current supply for charging the car battery will stop because the electrical energy from the alternator stops.

As a result of damage to the alternator due to worn-out carbon brushes, it will cause the car battery run short due to running out of electrical power. When the car battery runs out of electricity, the car will break down.

3. The stator and or rotor coils are broken or burned

The next alternator failure that also occurs is the stator coil and rotor broken or burned. Coils are made of copper wire coated with enamel that will react when exposed to a magnetic field. When an electric current is flowing, it will produce a magnetic field.

The stator coil serves to generate electricity, while the rotor coil functions to generate a magnetic field. Without electromagnetic cooperation between the stator and rotor, the alternator cannot generate an electric current.

Common alternator problem that occurs with these two coils is the result of breaking or burning. The causes of breaking or burning the windings in these two components can be various, such as loose soldering (production defects) or being subjected to rotating rotors due to shaking and rubbing against each other.

The resulting damage to these two components is the charging system does not work. The battery will drain fast, the alternator fuse blows, or the car breaks down.

Also read:- Alternator parts and function

- How to test an alternator without multimeter

- What makes an alternator go bad

4. The alternator bearing is stuck or jammed

The other alternator failure is the alternator bearing stuck or jammed. Alternator bearings are installed as rotor bearings so that the rotor can rotate smoothly. They are generally installed at both ends of the rotor.

Alternator bearings are generally solid and durable, but the life factor, rust, and being flooded can also affect the alternator bearing's durability. This damage can cause the alternator to fail or jam.

Bearing jammed causes the alternator pulley to not rotate smoothly, due to which the alternator belt is damaged. If it is obliterated, the rotor will easily rub against the rotor so that the coil breaks out.

5. The alternator pulley is tilted or dented

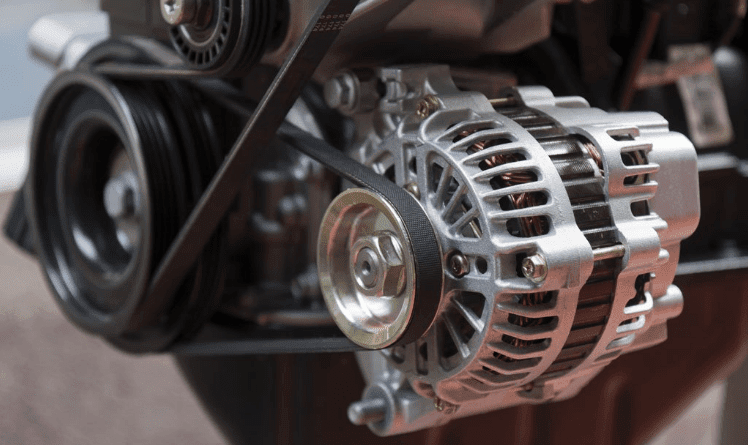

The last alternator failure that we know is the alternator pulley bent or dented. The alternator pulley is a component that will connect the alternator to the engine. When the engine rotates, the alternator immediately rotates.

Alternator belts are used to connect the engine to the alternator, which can be in various shapes, such as v-belts, ribbed belts, etc. This alternator belt is attached to the pulley.

When the alternator pulley is dented or tilted, the effect will impact the condition of the belt. The belt will slip easily and even makes a squeaking noise, and the worst is the alternator belt broken.

When the alternator belt is broken, it makes the alternator problem and will not be working anymore. It means that your car charging system is stopped, and your car will break down soon after your car battery drains out.