How Idle Air Control (IAC) Valve Works?

The Idle Air Control System is a system that functions to regulate the engine idling rotation speed so that it always remains stable to prevent the engine from stalls due to changes in engine load.

The Idle Air Control System does not exist on cars with Electronic Fuel Injection (EFI) systems only; cars with carburetors also have an Idle Air Control System. It's just that the difference is the shape of the components and how they work, if the carburetor is more mechanical, while the injection car is more electric.

However, in this article, we only limit the discussion of how the IAC (Idle Air Control) works on the Electronic Fuel Injection engine (EFI). Check out the explanation below.

I. Overview of the Idle Air Control (IAC) system

As long as the engine is running, the engine speed will always vary according to engine load conditions and driver behavior. When the gas pedal is not pressed, the engine will return to idling speed. Idling speed is an engine rotation set to always be in an efficient position for the engine and comfortable for the driver.

However, if the engine is given full load when the rpm is idling, the engine rpm will drop and may cause the engine to stall.

Here are some examples of conditions when the engine is at full load

- When the engine is first started in cold engine conditions

- If there is an electrical load, such as a radiator fan that is on or when the headlamp is on

- When there is a shift of the automatic transmission lever to the D position

- When the car's Air Conditioner (AC) is on

At this time, the engine requires additional air to prevent a decrease in engine speed. The addition of air when idling at full load will automatically increase the engine rpm rotation.

For example, if the engine idling speed when the AC is off is 800 rpm, then when the AC is on (there is an engine load), the engine idling speed will increase to 850 rpm.

Therefore, an Idle Air Control System is needed to run the engine normally and remain comfortable to use.

II. How the Idle Air Control (IAC) system works

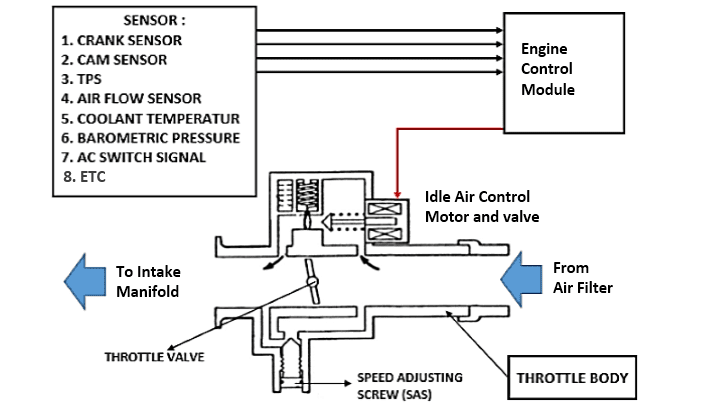

The Idle Air Control (IAC) system on an injection-engined car works electrically, where this system is controlled and regulated by the Engine Control Module (ECM). Look at the system IAC diagram below.

The ECM will receive input data from various sensors in the engine such as the Crank Angle Sensor (measuring engine speed), Coolant Temperature Sensor (measuring the temperature of the cooling water), Air Flow Meter (measuring the incoming air), and others.

The ECM then processes the collected data to produce a new data conclusion used to drive the IAC motor (Stepper motor) to close or open the idle port on the Throttle Body according to the engine's needs.

Read Also:- Symptoms of a bad Idle Air Control (IAC) valve

- The causes of engine rpm going up and down at idle

- 4 Causes engine high rpm at idle

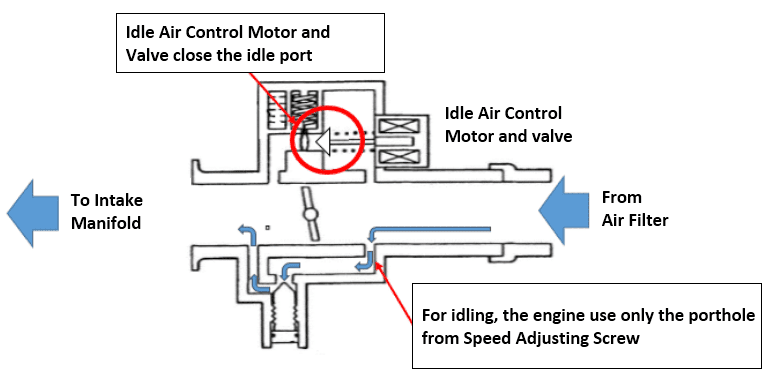

A. When idling without loads

When the engine is in the idle rpm position with no load, the motor IAC position will close the bypass hole from the idle port. The incoming airflow from the air filter will only flow through the Speed Adjusting Screw (SAS) hole.

Pay attention to the position of the IAC motor that closes the hole when the idling condition is no load in the following picture.

We can turn this Speed Adjusting Screw manually to get the engine rpm for ideal idling (generally, the idling rpm is between 750 rpm - 850 rpm).

The IAC motor does not automatically close completely but follows the real data obtained from each sensor. In addition, the magnitude of the closing position of the valve on the IAC motor is very dependent on the conditions that exist in the engine at that time, such as when the engine temperature conditions are at the ideal temperature, the engine speed is normal, and the engine load is not running.

B. When idling with loads

When the ECM receives input data that the engine is getting loads such as the AC is on, the headlamp is on, the radiator fan motor is on, the ECM will move the IAC motor to open the Idle porthole so that the engine gets additional air supply.

Pay attention to the open position of the IAC motor in the picture below.

The airflow of an idling rpm where there is a load will flow both through the SAS port and the Idle port. It will increase the volume of air entering the engine. As a result, there will be an increase in the number of engine rpm.

All conditions open and close the IAC motor is not necessarily fully open or fully closed. It depends on the engine's condition, whether it's rotation, temperature, or other things based on data from sensors throughout the engine, especially for the Idle Air Control (IAC) System.