Common Rail Diesel Injector Types

Since its discovery by Rudolf Diesel, diesel engines have encountered significant developments. At the beginning of development, diesel engines are considered less good than gasoline engines. This comparison is used for motorized vehicles so that many ordinary people still misjudge the capabilities of diesel engines.

When every vehicle entered the electronic control era, diesel engines began to experience significant changes in quality matched gasoline engines. The diesel engine has encountered a change in its fuel spraying system that uses "Common Rail" technology.

This technology is very similar to Electronic Fuel Injection (EFI) works on gasoline engines. By relying on the Electronic Control Module (ECM), it expects that the common rail diesel engine will perform better than conventional diesel engines.

One component that gets a significant change from conventional diesel to common rail diesel engines is the injector. The injector serves to atomize the fuel into the combustion chamber with very high pressure. The common rail diesel injector is divided into two types referring to the working mechanism. Below is common rail diesel injector types.

I. Electromagnetic Common Rail Diesel Injector

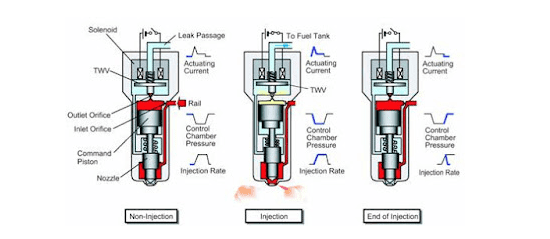

1. The way it works is when activated by the ECM (electronic control module). The electromagnetic solenoid above the injector allows high-pressure fuel to lift the needle from its holder, and injection is performed. As soon as the solenoid is deactivated, fuel pressure forces the needle in its holder, stopping the injection. Multiple injections can occur in one cylinder combustion cycle to control explosive combustion to reduce emissions and noise.

2. The fuel pressure on the fuel rail will vary dramatically depending on driving and operating conditions. It is all set by the ECM to change the injector opening time. Pay attention to safety requirements due to very high fuel pressure.

3.High operating voltage and current are required to start the injection. Typically, the Opening Voltage is from 60 - 100V.

4.The diesel backflow port is located on the injector, which can help with diagnosis. The reading of the resistance value for the solenoid circuit on the injector is approximately 1 Ohm or less; this data is very useful for determining the damage.

5. The procedure after installation so that the injector can work properly are:

- We must enter each injector QR code into the ECM.

- This procedure is also Pilot Injection on some systems.

- General coding instructions are included with newly purchased CRD injectors. It is also required a suitable scanner for this procedure.

Note: Fuel contamination is a major cause of premature failure. Please, do not install the new injector until the fuel system is completely clean to avoid damage to the new injector.

Read also:- Common rail diesel starting problems

- Diesel supply pump HP3 components and their functions on common rail engine

- Symptoms Of Bad Suction Control Valve (SCV) In Common Rail Diesel Engines

II. Piezoelectric Common Rail Diesel Injector

1. The internal construction of Piezo injectors varies with the Electromagnetic type. The internal semiconductor stack expands when activated (instead of a solenoid), resulting in a faster injector opening time. It allows increased primary pre-and post-injection work for individual cylinder combustion cycles, resulting in good combustion, a smoother, cleaner, and quieter engine. Most manufacturers today use this type of injector in new vehicles.

2.Fuel pressure on the fuel rail is generally greater in this system which allows smoother fuel injection.

3. This type of injector's operating voltage and current are 100 - 400V and - 20 to +20 Amp.

4. Reverse injector polarity by ECM is used to retract the semiconductor to stop injection quickly.

Warning: Removing the injector wire harness from the injector while the engine is running is not recommended because the injector "may" continue to inject fuel and cause engine damage.

5. Reading resistance on the internal injector type Piezo is 150k Ohm to 210k Ohm. Use this data as identification of damages.

6. Post-installation procedures are required for this type of injector system.

7. Similar to the Electromagnetic type, a return fuel port is required for Piezo-type injectors. It is useful for testing purposes.

Note: Fuel contamination will also damage these injectors.

What is the future of Piezo-type injectors?

The Volvo and Toyota lineup (examples only) are now equipped with CRD injectors that incorporate a fuel pressure and temperature sensor. Allowing an accurate injection amount matching each cylinder. More useful information will result in more efficient engine operation.