What does a knock sensor do?

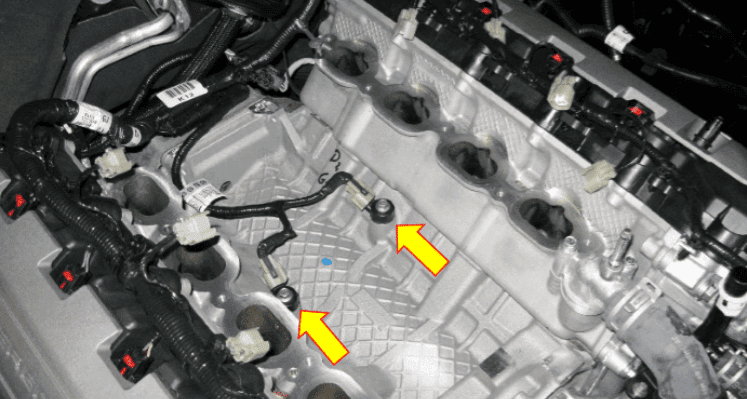

The knock sensor is one of the Electronic Fuel Injection (EFI) system sensors that detect the magnitude of vibrations and knocks that occur in the engine. Therefore, this knock sensor is generally installed directly on the wall of the engine block.

Engine knocking in gasoline engines occurs due to a collision between several pressure waves with the engine cylinder wall. These collisions generally come from the "pre-ignition" event in the engine cylinder, which is the combustion of the air and fuel mixture is happens before the spark plug sparks.

The occurrence of knocking on the engine will impact the engine's performance. The engine becomes less powerful but more fuel-intensive. Therefore, a knock sensor is used, which reduces the knocking symptoms that occur in the engine.

In a simple way, the knock sensor monitors the combustion process in the engine. Its signal helps the engine control to prevent knocking combustion and therefore protect the engine control.

How the knock sensor works?

Inside the knock sensor, there is an electronic component called piezoelectric. This piezoelectric will generate a voltage value sent to the Engine Control Module (ECM) when there is a knock or excessive vibration on the engine.

Yes, this piezoelectric component must have been synchronized with the regular beat of the engine. When there is a change in the pattern and frequency of the beats, this piezoelectric will generate a voltage value that enters the ECM and then is used to the ECM as input data. Pay attention to the electrical schematic of the knock sensor with the ECM in the image below.

When the engine is knocking, the knock sensor will detect and absorb vibrations and knocks that happen. The vibrations make the piezoelectric generate an output voltage value as input data for the ECM.

Read Also:- What does an oxygen sensor do?

- What does MAP sensor do?

- What does the intake air temperature sensor do and works?

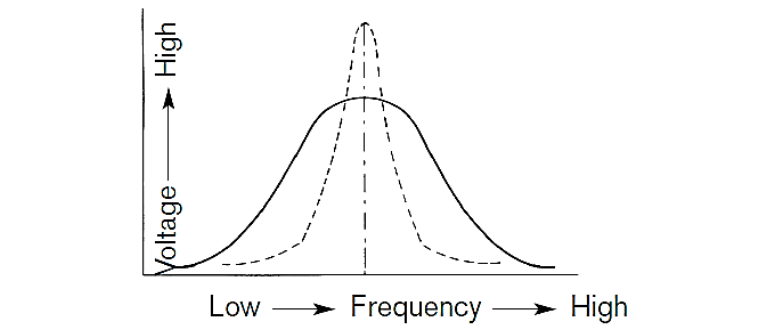

The greater the knocking and vibration in the engine, the higher the voltage value issued by the knock sensor to the ECM. The ECM then reads this change in voltage as a sign that a knock has occurred in the engine. Pay attention to the graph that shows the change in voltage when there is a knock on the knock sensor below

When the ECM reads that a knock has occurred based on the value on the knock sensor, the ECM will adjust and lower the Ignition timing by several degrees so that the knocking symptom can be reduced or eliminated.

The ECM will continue to evaluate these conditions while the engine is rotating and return to advancing the ignition timing position so that the engine can work optimally. The reduction in ignition timing will be carried out by the ECM when knocking occurs again.